AQUAPOD Sewage Treatment Plant

The AquaPod sewage treatment plant is a larger sewage treatment system, using our proven MBBR technology. The range starting at 50 persons, is designed to fit after an on-site constructed or locally sourced primary tank, an existing septic tank (subject to suitability) or a failing sewage treatment plant.

The AquaPod processes the primary tank effluent, producing a clear, odourless and non-polluting effluent, capable of being discharged, safely, into the environment.

The AquaPod sewage treatment plant provides an affordable solution for sites where it is more economically viable to build the Primary Tanks on-site, or source them locally - typically where tanks have to be imported.

It is also suitable as a cheaper alternative to replacing a soakaway drainfield, if a suitable watercourse is present.

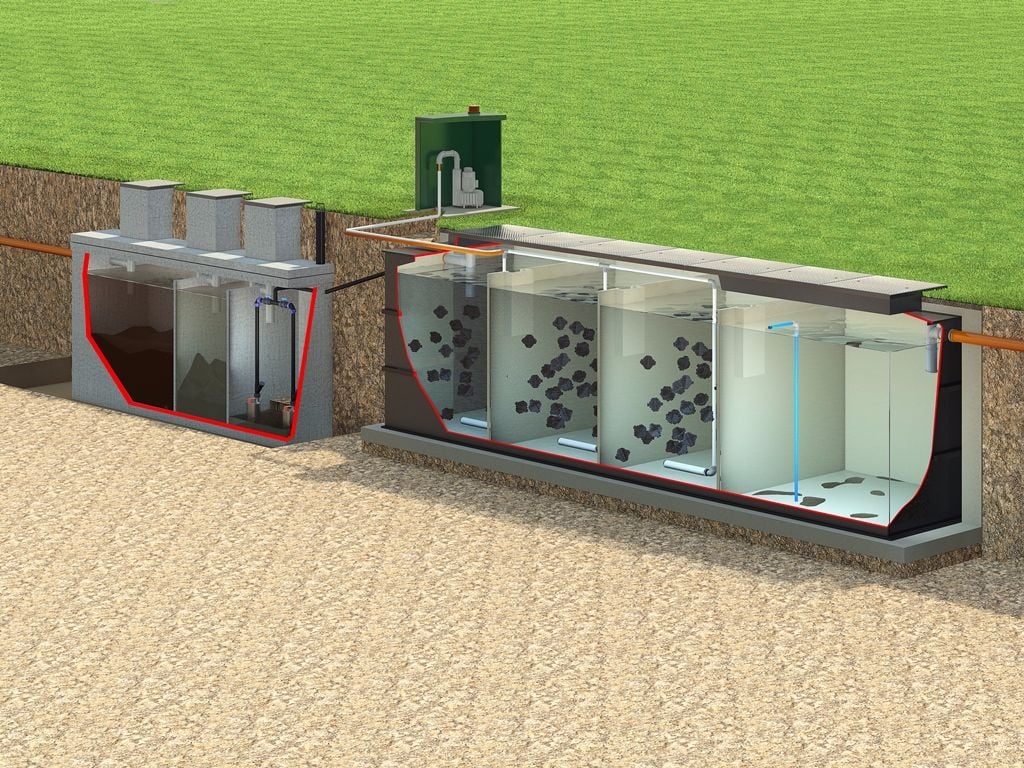

HOW THE AQUAPOD SEWAGE TREATMENT PLANT WORKS

Stage One

The raw sewage enters the Primary Tank.

WTE can provide detailed drawings and specifications for this Primary Tank.

The Primary Tank separates the solids from the liquid part of the effluent.

This Primary Tank Effluent is pumped into the AquaPod sewage treatment plant via a pumping chamber, which can be either integral or external to the Primary Tank.

Stage Two

The primary effluent is pumped into the top of the AquaPod tank to eliminate wasted space and to reduce the depth of the dig required. It also makes maintenance much easier, as all components are close to the surface.

Air is blown into the multi-chambers of the AquaPod Biozone from an air blower housed in a Kiosk. This provides the oxygen required to establish an aerobic bacterial population which digests the pollutants in the sewage.

Stage Three

The cleaned effluent then overflows into the last chamber - the Final Settlement Tank - where any remaining fine solids settle to the bottom and clean liquid exits the tank by gravity. A pumped outlet is available, if required.

THE SLUDGE RETURN PROCESS

The settled sludge in the Final Settlement Tank is returned back to the Primary Tank via a Sludge Return Pipe (in BLUE). This is operated from the Air Blower, as some air is diverted to operate an Air Lift Facility in the Final Settlement Tank.

This settled sludge 'seeds' the Primary Settlement Tank with the correct bacteria needed for the treatment process.

It prevents the Primary Tank from becoming too septic and anaerobic, as it contains fully oxygenated effluent.

It also keeps the Final Settlement Tank clean and free from the sludge that could contaminate the final effluent that leaves the treatment plant.

AQUAPOD TREATMENT PLANT OPTIONS

ABOVE GROUND (AG) INSTALLATION

The AquaPod is also available as an ABOVE GROUND option

It works in exactly the same way as the below ground version, using primary tank effluent which is pumped upwards into it.

The above ground installation is far cheaper than a below ground one and eliminates the installation problems that are encountered with high water tables, rock and poor ground conditions.

ULTRA-VIOLET LIGHT DISINFECTION

The AquaPod can be followed by a UV Light Treatment Unit, if removal of bacteria and viruses is required.

This enables the final effluent to be used for drip or sub-surface irrigation, in most circumstances.

This is very useful for gardens in low rainfall regions.

NOT to be used for spray irrigation.

FINAL EFFLUENT QUALITY OPTIONS

The AquaPod is available with a choice of 3 different Effluent Quality options, depending on the particular environmental requirements:

All figures are in MG/L.

BOD:SUSPENDED SOLIDS:NH3

GRADE 1 - 5:15:5

GRADE 2 - 10:30:10

GRADE 3 - 20:30:20

The Grade 3 effluent is the Royal Commission Standard. Most sewage treatment plants are designed to meet this standard, but the AquaPod can be designed to do much better, if required.